Z950R

- 7-Iron™ PRO Mowing Deck

- Mulch On Demand™ Available

- RearDischarge Deck

- Propane Option Available

- Cross-porting hydraulic transmission

Price may vary based on location and options.Apply for financing

Don't let a flat stop you

The Michelin X Tweel performs like a pnuematic tire, but without the risk and costly downtime associated with flat tires and unseated beads. Never have to worry about air pressure.

Strongest decks on the market

John Deere's exclusive 7-Iron decks are 5.5 inches deep and 7-gauge sturdy, which explains why they're the strongest, most durable mowing decks in the industry.

features

Z950M and Z950R engine

Z950M and Z950R engine

The Z950M and Z950R are powered by an air-cooled, vertical shaft engine:

- 27-hp (20.1-kW) gas engine

Engine features include:

- Overhead valve design

- More horsepower and torque per cubic inch of displacement

- Better fuel efficiency

- Full-pressure lubrication with full-flow filter

- Reduces engine wear by ensuring proper lubrication, even when operating on hillsides or uneven terrain

- Oil filter helps keep oil clean for increased engine life

- V-twin big block design

- Vertical shaft

- Easy-access, dual-element air filter with quick-release latch

- 30-amp alternator

- Fuel pump

- Complies with strict Environmental Protection Agency (EPA) and California Air Resources Board (CARB) emission standards without loss of horsepower or torque

- Aluminum block engines

- Effectively dissipate heat

- Lightweight and strong construction

- Extend engine life due to elimination of debilitating engine temperatures

- Air-cooled engine design

Engine service

Engine oil check/fill and drain tube (shown on Z740R)

Engine oil check/fill and drain tube (shown on Z740R)

The engine is easy to service, including changing the oil:

- The engine oil check/fill tube is located at the top of the engine and easy to see and reach.

- A flexible oil drain tube is included to conveniently drain oil into a pan, thus eliminating oil spills.

Air cleaner filters out dust that can damage an engine

Engine air cleaner

Engine air cleaner

Air cleaner cover removed

Air cleaner cover removed

ZTrak™ Z900 Mowers are equipped with a dual-element, canister-style air filter, easily accessible from the rear of the machine without tools.

- The filtration system pulls clean air from above the engine, in turn filtering out the dust that can damage an engine over time.

- Filters are extremely easy to change when required.

- Pre-cleaner provides more protection against contamination in dusty and dirty applications.

Mow all day on a single tank of fuel with efficient and easy-to-fill fuel tank

Fuel tank and filler neck

Fuel tank and filler neck

Fuel filler neck

Fuel filler neck

The ZTrak™ Z900 Mowers are equipped with one single-fill, top-draw fuel tank:

- 11.5-U.S. gal. (43.5-L) capacity enables operators to mow all day without refueling.

- The fuel gauge makes it quick and easy to see how much fuel is in the tank.

- Top draw provides added safety.

- A large fuel-filler neck is angled to make it easy for an operator to complete the fueling process.

Under normal conditions, load, and operation, fuel consumption for carbureted Z900 ZTrak Mowers is 1.5 U.S. gph (5.7 L/hr) to 2.2 U.S. gph (8.3 L/hr), depending on the horsepower and conditions.

54-in. (137-cm) 7-Iron PRO Mower Deck

54-in. (137-cm) 7-Iron PRO Mower Deck

72-in. (183-cm) 7-Iron PRO Mower Deck

72-in. (183-cm) 7-Iron PRO Mower Deck

7-Iron PRO mower decks have demonstrated quality, performance, and durability. They deliver a high-quality cut in diverse conditions.

Key features of the 7-Iron PRO mower deck:

- Deck is forged from 7-gauge, 0.179-in. (4.6-mm) steel to minimize the number of welds and provide a smooth underside with fewer sharp corners for reduced material buildup.

- Significantly fewer welds on the deck shell to wear or break - it is forged from a single sheet of steel rather than multiple fabrications. An anti-skid step on the deck provides easy machine mounting.

- Extra reliability and long life with cast-iron blade spindle housings.

- Higher blade tip speed than many competitors - approximately 18,500 fpm (5,639 m/min) for more blade cuts per inch mowed.

- A deep-deck design of 5.5 in. (14 cm) delivers excellent airflow so material can be processed quickly and efficiently.

- The wider and higher discharge opening provides even clipping dispersal for an excellent finished appearance in all conditions.

- Quick-release belt covers do not require tools or the removal of a ring clip; just lift one corner of the cover and rotate it slightly to remove.

- A hole in the deck tab is provided for use of an optional ring clip for extra security, if desired.

- This makes it quick and easy for you to clean out trash that may collect around the spindle sheave.

Mower rectangular leading-edge reinforcement

Mower rectangular leading-edge reinforcement

Dual-captured anti-scalp wheel

Dual-captured anti-scalp wheel

- Deck has rectangular leading deck edge reinforcement and the rounded corners of the forged deck help distribute impact stress to reduce the potential of damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

- Dual-captured front and rear anti-scalp wheels provide deck flotation over even the toughest terrain.

- Three 1-in. (2.5-cm), cold-forged spindles are heat-treated for strength without bulk and are supported by ball bearings, providing reliability and performance; spindle housings are ribbed cast iron providing both excellent strength and heat dissipation.

- The trim edge of the deck is equipped with a bumper that provides great abrasion resistance to protect the machine and the property.

- The front edge is raised above the blade plane to allow even cutting of tall grass and is reinforced with a square bar for durability. The front baffle has been redesigned to better manage airflow and control clippings.

- Three spindle grease fittings are accessible from the top.

- Blade overlap is 1.6 in. (40.6 mm), nearly 0.79 in. (20 mm) greater than previous decks, to reduce striping between blades.

- Quick-change, cutting-height adjustment.

Extra reliability and long life with cast-iron blade spindle housings

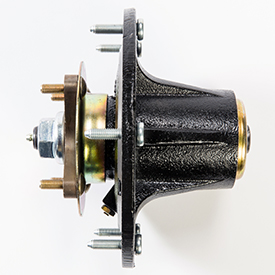

Cast-iron mower spindle

Cast-iron mower spindle

Cast-iron mower spindle

Cast-iron mower spindle

On every commercial mower deck there are three 1-in. (25-mm) spindles that are cold-forged and heat-treated for strength. Spindles are supported by precision ball bearings that provide great performance and reliability.

- Superior impact strength provided by ductile cast-iron material.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Easy access grease fittings are mounted at the top of the spindle shafts for convenience.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- Chance of deck shell damage is minimized with the 8-in. (20.3-cm) diameter housing and six mounting bolts that distribute loads and impacts.

- Ability to be reliably rebuilt is provided by use of cast iron.

7-Iron PRO mower deck

Mower deck |

Z920M |

Z930M |

Z950M |

Z955M EFI |

Z960M |

Z965M EFI |

Z975M EFI |

Z950R |

Z955R EFI |

Z965R EFI |

Z970R |

Z985R EFI |

48-in. (122-cm) 7Iron PRO side- discharge |

x |

|

|

|

|

|

|

|

|

|

|

|

54-in. (137-cm) 7Iron PRO side- discharge |

x |

x |

|

x |

|

|

|

x |

|

|

|

|

60-in. (152-cm) 7Iron PRO side- discharge |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

x |

|

72-in. (183-cm) 7Iron PRO side- discharge |

|

|

x |

|

x |

x |

x |

x |

|

x |

x |

x |

Mower deck step and trim-edge bumper shown on 54-in. (137-cm) mower

Mower deck step and trim-edge bumper shown on 54-in. (137-cm) mower

The deck step safely aids the operator's entrance and egress from machine.

60-in. (152-cm) Rear-Discharge Mower Deck

60-in. (152-cm) Rear-Discharge Mower Deck

72-in. (183-cm) Rear-Discharge Mower Deck

72-in. (183-cm) Rear-Discharge Mower Deck

For professional landscapers and government municipalities requiring rear discharge placement of grass and debris, John Deere FastBack PRO rear-discharge mower decks deliver a commercial zero-turn mowing solution for both gas and diesel machines. Advantages of a rear-discharge mower include:

- Less chance of damage from objects being thrown from the mower deck

- Time savings with the ability to mow closely around fixed objects with either side of the deck

- A cleaner mowing experience by lessening the amount of debris that can blow onto the operator

A rear-discharge mower deck is ideally suited for:

- Schools

- Parks

- Playgrounds

- Traffic areas (city boulevards, roadsides, etc.)

- Areas with long, grassy spots that need to be cut, where you are not as concerned about wide dispersal of grass (park areas, roadsides, etc.)*

*NOTE: Operators maintaining turf outside of target areas are encouraged to evaluate rear-discharge dispersion through a cut quality demonstration to ensure satisfaction.

Compatibility

Mower deck |

Z930M |

Z950M |

Z955M EFI |

Z960M |

Z975M EFI |

Z950R |

Z955R EFI |

Z965R EFI |

Z970R |

Z985R EFI |

Z994R |

Z997R |

60-in. (152-cm) FastBack PRO rear- discharge |

x |

|

x |

x |

x |

x |

|

|

|

|

x |

x |

72-in. (183-cm) FastBack PRO rear- discharge |

|

x |

|

x |

x |

|

x |

x |

x |

x |

x |

x |

Commercial-quality deck design

A large volume of material can be thoroughly processed with the deep-deck design:

- Unique baffling system is designed to reduce clumping and windrowing often associated with rear-discharge mowers.

- Efficiency is enhanced with baffles surrounding each blade to control material as it is moved to the rear.

- Material exits the deck quickly as the baffles are lower at the rear.

- Movement of material is controlled to minimize the likelihood that clippings are thrown onto unwanted areas.

- Less debris gets on the operator as material is directed to the rear and toward the ground.

- Debris is kept low and directed into the turf by the flexible rear shield.

Level cut

Center deck rollers and left wheel

Center deck rollers and left wheel

Right-rear deck wheel

Right-rear deck wheel

The deck is suspended from and supported by the machine to provide a level cut. Mower deck wheels and rollers help smooth out the mowing job in uneven conditions and reduce the chance of scalping the lawn:

- Two wide front rollers at the center of the mower support the deck when necessary to prevent scalping.

- Wheels at all four corners protect the deck from scalping at the sides of the mower.

- Continued effectiveness results from wheels and rollers that are double captured for extra strength, which reduces the chance of damage.

- Height of rollers and wheels is adjustable to suit mowing conditions.

- Higher setting (shown in images) are used when mowing at lower cut heights and for rougher conditions at all cut heights where you want to reduce the chance of the wheels hitting the ground.

- Lower settings are used for higher cut heights and for helping to smooth out the mowing job.

- Mower cut height is adjustable from 1 to 5.5 in. (2.54 to 14 cm) in 0.25-in. (0.64-cm) increments from the machine operator’s station.

Heavy-duty components for long life

Strong, reinforced deck

Strong, reinforced deck

Right trim-side wear guard

Right trim-side wear guard

These rear-discharge decks are designed to stand up to heavy-duty commercial use:

- Superior strength and durability come from a 7-gauge, 0.179-in. (4.6-mm) steel deck.

- Experience extra strength and long life with a fabricated deck design that is formed, welded, and reinforced for extra protection from damage.

- The front of the deck is protected from damage by a 1.5-in. (3.8-cm) tall by 0.5-in. (1.3-cm) thick solid steel bar welded to the mower deck for additional strength.

- Both sides of the deck have bumpers that are made from compression molded ultra-high molecular weight (UHMW) polyethylene plastic.

- The bumpers provide great abrasion resistance to protect the machine and the property.

- Additional strength is provided by a 0.5-in. (1.3-cm) by 0.5-in. (1.3-cm) thick solid steel bar.

Universal joint and cast-iron gearbox (Z997R)

Universal joint and cast-iron gearbox (Z997R)

Cast-iron blade-spindle housing

Cast-iron blade-spindle housing

Durability is designed into the mower blade drive system:

- Reliably powered by a universal joint shaft drive from the vehicle transmission to a heavy-duty right-angle, cast-iron gearbox (Z997R)

- Dependable v-belt drive system

Extra reliability and long life are provided by cast-iron blade spindle housings:

- Ductile cast-iron material provides superior impact strength.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- Chance of deck-shell damage is minimized with the 8-in. (20.3-cm) diameter housing and six mounting bolts that distribute loads and impacts.

- Ability to be reliably rebuilt is provided by use of cast iron.

Ease of service

Quick-release belt cover

Quick-release belt cover

Cast-iron spindle housing assembly

Cast-iron spindle housing assembly

Minimal service requirements increase uptime:

- Quick-release belt covers do not require tools or the removal of a ring clip; just lift one corner of the cover and rotate it slightly to remove.

- A hole in the deck tab is provided for use of an optional ring clip for extra security, if desired.

- This makes it quick and easy for you to clean out trash that may collect around the spindle sheave.

- Convenient spindle greasing with fittings at the top of spindle shafts are accessible through a hole in the top of the spindle/belt covers.

- The center spindle is accessed by no-tools removal of the vehicle floor pan.

- There is only one belt to service.

Extra convenience

Serrated-tread step

Serrated-tread step

Extra convenience and security are provided by a serrated surface that is welded to the top left corner of the deck, providing additional traction when entering and exiting the operator station.

ComfortGlide fore/aft suspension

ComfortGlide fore/aft suspension control lever

ComfortGlide fore/aft suspension control lever

The seat has the ComfortGlide fore/aft suspension system that gives superior ride comfort over uneven areas:

- Seat can travel up to 2 in. (50.8 mm) fore and aft to absorb bumps for a significant enhancement to ride comfort.

- Control lever provides the ability to easily lock out fore/aft suspension movement if desired.

- One lever has three functions:

- Slide seat forward and back 3 in. (10.2 cm) to allow the operator the ability to choose the leg room needed

- Activate ComfortGlide fore/aft seat suspension

- Lock out ComfortGlide fore/aft seat suspension

Fully adjustable suspension seat with armrests

Fully adjustable, mechanical suspension-seat

Fully adjustable, mechanical suspension-seat

Suspension seat control

Suspension seat control

A fully adjustable suspension seat with armrests is standard on R Series:

- Adjustable back angle is provided for individual operator comfort.

- Adjustable lumbar support helps to suit the needs of the operator.

- A suspension seat control dial gives easy adjustment for operator weight and ride comfort.

- A convenient seat latch provides ease of lifting the seat.

Designed for operator comfort

Operator station

Operator station

Two-lever hydrostatic control provides the following:

- The operator can select the ground speed and direction control simply by moving levers forward or reverse.

- Positive neutral lock position for levers provides added safety.

- Brake & Go operator-presence system returns levers to the neutral position when the brake pedal is actively engaged.

- Starting the machines is as easy as starting a car. It no longer matters if the control levers are extended out or pulled in, as long as the parking brake is engaged. Just turn the key and go.

- Wide-bend, large-diameter steering levers swing out easily for entry and exit from the operator platform.

Foot pegs

Foot pegs available as standard on R-spec Z900’s

Foot pegs available as standard on R-spec Z900’s

Foot pegs help in providing the operator with a comfortable foot placement:

- Location and angle of foot pegs can be adjusted for individual operator comfort.

Foot platform isolators

Foot platform isolators

Foot platform isolators

Foot platform isolators provide the operator with added comfort:

- Vibration to the legs and feet is reduced.

Brake & Go starting system

Parking brake pedal (Z900R Series)

Parking brake pedal (Z900R Series)

Parking brake lever (Z900 M Series)

Parking brake lever (Z900 M Series)

The Brake & Go starting system is a John Deere exclusive. This feature makes the starting process on all ZTrak™ mowers easier, while also making it possible to remove two interlock switches from the machine.

The Brake & Go starting procedure helps a novice operator look and feel like a professional. To start the machine, the parking brake must be engaged. It does not matter whether the power take-off (PTO) switch is on or off, nor does it matter if the control levers are pulled in or in the out position.

As long as the parking brake is engaged, the machine will start. When the parking brake is applied, the control levers cannot be moved to the forward or reverse positions.

Adjustable levers

Adjustable levers

Adjustable levers

The motion control levers have two height positions and can also be adjusted forward or rearward within the slotted holes. The levers should be adjusted so the operator can achieve a full range of control operation comfortably.

Tracking adjustment

Tracking adjustment

Tracking adjustment

The easy-to-turn (from-the-seat) tracking adjustment allows operators to keep their mowers straight and able to produce professional striping results.

Onboard storage and cup holder

Onboard storage

Onboard storage

Cup holder

Cup holder

Several storage areas are provided on the ZTrak machines. A convenient cup holder is also available.

Right-hand control panel

Right-hand control panel (carbureted models)

Right-hand control panel (carbureted models)

Right-hand control panel (EFI models)

Right-hand control panel (EFI models)

The controls are grouped together on the right console, providing one central location for:

- Rocker-type PTO switch

- Height-of-cut knob with transport lock

- Key switch

- Hour meter (carbureted models) or display panel (EFI models)

- Throttle

- Separate choke control

- Easy choke operation yields less fouling of plugs

- No choke required for the electronic fuel injection (EFI) models

Easy-to-operate height-of-cut adjustment enables on-the-go changes

Mower deck height adjustment knob

Mower deck height adjustment knob

An easy-to-use cutting-height lift system allows the operator to adjust the mower deck height with no tools and minimal effort. The easy-to-grip knob allows operators to dial in the desired height of cut (HOC).

Cutting height can be adjusted from approximately 1 in. to 5.5 in. (2.5 cm to 14 cm). Each increment on the knob adjusts the HOC approximately 0.25 in. (0.64 cm). The deck can also be raised and locked in a transport position to provide maximum ground clearance when moving the machine from one area to another.

The transport lock function allows the deck to be returned to the previous HOC after being in the transport position:

- Use the foot-lift pedal to lift the deck and engage the transport lock.

- Rotate the knob to adjust from 1 in. to 5.5 in. (2.5 cm to 14 cm) in 0.25-in. (0.64 cm) increments.

This design increases productivity by allowing operators to change the cutting height without having to leave the seat.

Comfort and convenience handles

Comfort and convenience handles

The comfort and convenience package combines large, ergonomically angled control levers with specially padded grips to provide unmatched comfort and reduced fatigue:

-

Keeps hands on the control sticks to minimize equipment damage and make them more comfortable over long operating days.

The control levers have built-in electronic controls to raise or lower the mower deck or disengage the mower blades.

Control buttons

Control buttons

The push button (A) on the left motion control lever raises the mower deck.

The push button (B) on the right-hand control lever shuts off the PTO.

Once the PTO has been shut off using the button, the PTO switch must be pushed down and pulled up again to engage the PTO.

Z960M ZTrak™ Mower

Z960M ZTrak™ Mower

Z950R ZTrak Mower

Z950R ZTrak Mower

M Series 3-year, 1200-hour bumper-to-bumper warranty

An exclusive 2-year, unlimited hour/3-year, 1200-hour (whichever comes first) bumper-to-bumper warranty is standard for all John Deere M Series Mowers. The warranty is best in its class and places John Deere at the forefront of commercial mowing. It is also hassle free, with one company handling all of the paperwork.

NOTE: 36 months or 1200 hours, whichever comes first. For the first 24 months, there is no hour limitation.

R Series 3-year, 1500-hour bumper-to-bumper warranty

An exclusive 2-year, unlimited hour/3-year, 1500-hour (whichever comes first) bumper-to-bumper warranty is standard on all John Deere R Series mowers. The warranty is best in the industry and puts John Deere at the forefront of commercial mowing. It is also hassle free, with one company handling all of the paperwork.

NOTE: 36 months or 1500 hours, whichever comes first. For the first 24 months, there is no hour limitation.

Mower decks are safety certified

54-in. (137-cm) 7-Iron PRO Mower Deck

54-in. (137-cm) 7-Iron PRO Mower Deck

Mowers decks are evaluated by the manufacturer (John Deere Turf Care) and conform to American National Standards Institute (ANSI) B71.4 2004 safety certification specifications for commercial turf care equipment.

Z970R shown with optional X® Tweel® Turf airless radial tire technology

Z970R shown with optional X® Tweel® Turf airless radial tire technology

The durability features of the frame are as follows:

-

Heavy-duty, thick-gauge, steel channel mainframe for strength and durability

-

Cast I-beam caster arms to handle the beating and pounding professional mowers receive

-

Wide-open access for maintenance and cleaning

Two-piece rear bumper provides protection

Illustration of ZTrak™ mower rear bumper

Illustration of ZTrak™ mower rear bumper

A steel rear bumper provides protection for the machine. The bumper is made of two pieces, making it easy to remove and install when using a material collection system (MCS).

A rear hitch can be added to the steel bumper for towing purposes. ZTrak M and R Series Mowers can tow up to 400 lb (181.4 kg).

Michelin, X, and Tweel are trademarks of Michelin North America, Inc.

Heavy-duty ground drive

Heavy-duty ground drive

The hydrostatic drive included with the Z900 Z Trak Mowers features two 13-cc (0.8-cu in.) unitized hydraulic pumps combined with commercial-grade, heavy-duty, 13-cc (0.8-cu in.) wheel motors into a single unit. The drive units feature cross porting, where the hydraulic fluid from the side doing the least work is filtered and then fed into the input of the side doing the most work. This ensures that the coolest fluid is going into the side working the hardest in order to provide the best performance during extended hillside operation in the same direction.

One pump and one motor drive each wheel on the Z900 ZTrak™ Mowers. This provides several benefits:

- Exceptional cooling in high load conditions

- Easy-to-check level and refill hydraulic oil

- Opens up access under the seat

Z970R left front view

Z970R left front view

The design of the Z900 Series makes many service components reachable and easily accessible from the ground.

- Large, open engine compartment at the rear of the machine provides convenient servicing and ensures the engine heat is directed away from the operator.

Flip-up foot panel

Flip-up foot panel

Flip-up seat

Flip-up seat

Onboard maintenance information

Maintenance label

Maintenance label

All ZTrak™ Mowers come with a maintenance label that is conveniently located inside the right-hand console. The label is written on English and Spanish languages and includes daily service check points, approximate fluid capacities, and tire pressures.

Quick response (QR) codes link to owner information web pages

QR code label

QR code label

To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located near the onboard storage. The owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalogs

- Maintenance reminder sheets

- Attachments

- Warranty statements

Diagnostics

Hour meter (Z920M shown)

Hour meter (Z920M shown)

Diagnostic chart

Diagnostic chart

On Z920M, Z930M, Z950M, Z960M, Z950R, Z970R models, the hour meter shows the number of hours the machine is run when the key switch is in the on position. It only counts the hours the engine is actually running. Machine diagnostics are the first step of a monitoring system to help operators quickly diagnose common downtime issues. A trouble code light is included on the hour meter.

Use of the hour meter and service interval chart helps determine when the machine will need service.

Z955R display panel

Z955R display panel

Service ADVISOR™ J1939 port

Service ADVISOR™ J1939 port

The Z955M, Z965M, Z975M, Z955R, Z965R, and Z985R EFI models include a modern display panel that speeds trouble shooting by providing error codes, system voltage, and circuit continuity tests that can report switch functionality and circuit continuity in seconds, without tools. These models are also equipped with a Service ADVISOR™ J1939 port to speed dealer diagnostics.

Z950R with 54-in. (137-cm) Mower Deck

Z950R with 54-in. (137-cm) Mower Deck

The spacious operator station has been designed for comfort, visibility, and ease of use:

- Getting on and off is easy with the flat operator platform.

- Convenient-to-use controls located close to the operator are color coded and designed for easy identification and operation.

The ROPS and seat belt work in conjunction to provide a protective zone around the operator:

- It reduces the operator’s risk of being crushed under the vehicle should it overturn.

- When used with the seatbelt, the ROPS can reduce the severity of injury in the event of a rollover.

- Use of the seat belt is recommended when operating with ROPS in the upright position.

ROPS in upright position

ROPS in upright position

ROPS in intermediate position

ROPS in intermediate position

ROPS in down position

ROPS in down position

Foldable ROPS and retractable seat belt are standard equipment:

- Position adjustment pins provide a good grip and make changing the angle of the ROPS easier.

- The ROPS can be pinned in an intermediate position to accommodate machines equipped with a material collection system.

- Under normal operation, the ROPS should be in the upright position.

- See Operator’s Manual for more information on ROPS.

- Door height of most garages will accommodate the machine with ROPS in the raised position.

- Easy-fold ROPS improves the ability to store the ZTrak™ mower in structures with a lower door opening.

| ROPS position | Height at top of ROPS |

| Upright | 73 in. (185 cm) |

| Down | 47 in. (119 cm) |

Optional light-emitting diode (LED) work lights

LED work lights

LED work lights

BUC11438 LED work lights provides the ability to mow at twilight and are available as a field installed attachment. See attachment story for compatibility and requirements.

Optional LED beacon light

LED beacon light

LED beacon light

BUC11406 LED beacon light signals to others that the machine is approaching and is available as a field installed attachment. See attachment story for compatibility and requirements.

TerrainCut™ Front and Wide-Area Mowers

TerrainCut™ Front and Wide-Area Mowers

ZTrak, QuikTrak, and commercial walk-behind Mowers

ZTrak, QuikTrak, and commercial walk-behind Mowers

Overview

A JDLink™ M Modem connects a commercial mower to the John Deere Operations Center, which enables you to manage your fleet more efficiently, increase productivity, and reduce labor costs. With a modem and Operations Center, you are always connected to the work in progress and can make timely adjustments to keep your fleet mowing.

JDLink M Modem

JDLink M Modem

JDLink M Modem

A JDLink M Modem is standard equipment on model year 2024 and newer TerrainCut Front and Wide-Area Mowers.

A modem can be field installed on:

- Model year 2024 and newer Z700 ZTrak™ Mowers

- Model year 2024 and newer gasoline-powered Z900 ZTrak Mowers

- Model year 2024 and newer Z994R ZTrak Mowers

- Model year 2021 and newer Z997R ZTrak Mowers

- Model year 2024 and newer Q800 QuikTrak™ Mowers

- Model year 2025 and newer R Series commercial walk-behind mowers

- Model year 2022-2023 TerrainCut Front Mowers

- Model year 2023 TerrainCut Wide-Area Mowers

See compatibility section for serial number breaks and requirements.

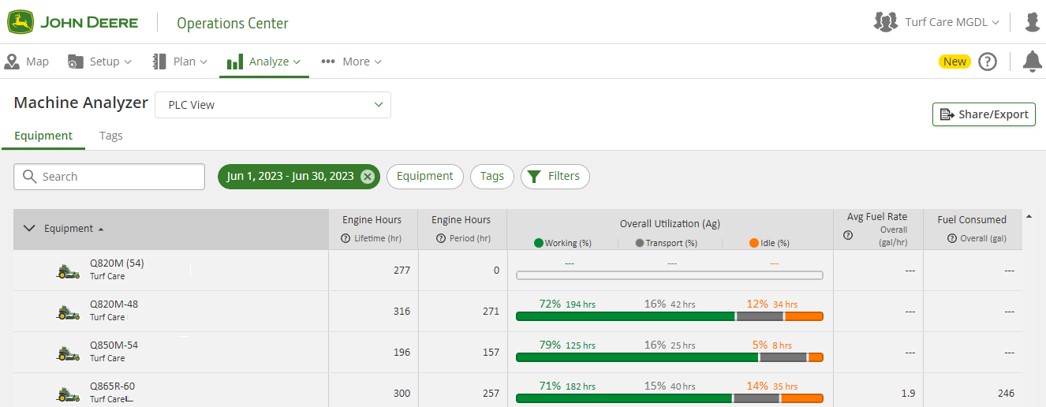

John Deere Operations Center

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps

The John Deere Operations Center tracks your fleet and provides tools to analyze mower data. The connected features vary by mower model.

Models |

Location and status |

GPS speed |

Geofencing and curfews |

Engine hours |

Maintenance planner |

Machine Analyzer Tool |

Fuel level |

Fuel consumption |

Diagnostic trouble codes |

Service Advisor Remote |

Z700 ZTrak Mowers |

X |

X |

X |

Key |

X |

X |

--- |

--- |

--- |

--- |

Z900 ZTrak Mowers with carbureted engines |

X |

X |

X |

Key |

X |

X |

--- |

--- |

--- |

--- |

Z900 ZTrak Mowers with EFI engines |

X |

X |

X |

Sync |

X |

X |

X |

X |

X |

X |

Z994R ZTrak Mowers |

X |

X |

X |

Key |

X |

X |

--- |

--- |

--- |

--- |

| Z997R ZTrak Mowers | X |

X |

X |

Sync |

X |

X |

--- |

X |

X |

X |

E Series QuikTrak Mowers |

X |

X |

X |

Key |

X |

X |

--- |

--- |

--- |

--- |

Q820M, Q850M, and Q850R QuikTrak Mowers |

X |

X |

X |

Sync |

X |

X |

X |

--- |

X |

--- |

Q865R EFI QuikTrak Mowers |

X |

X |

X |

Sync |

X |

X |

X |

X |

X |

X |

R Series commercial walk-behind mowers |

X |

X |

X |

Key |

X |

X |

--- |

--- |

--- |

--- |

1550 TerrainCut Front Mowers |

X |

X |

X |

Key |

X |

X |

--- |

--- |

--- |

--- |

1570, 1575, 1580, and 1585 TerrainCut Front Mowers |

X |

X |

X |

Sync |

X |

X |

--- |

X |

X |

X |

1600 TerrainCut Wide-Area Mowers |

X |

X |

X |

Sync |

X |

X |

--- |

X |

X |

X |

Location and status

Operations Center map displaying past locations of a mower

Operations Center map displaying past locations of a mower

Mobile view of Operations Center map showing GPS speed

Mobile view of Operations Center map showing GPS speed

The JDLink M Modem regularly transmits the location and operational status of each mower in the fleet so you can monitor mowing progress in Operations Center.

- Location history-Display of map with current and past locations of each mower.

- GPS Speed-Maps each mower’s current speed, based on GPS location data, so you can target operator training. GPS speed is only viewable on Apple iOS and Android mobile apps.

- Geofencing-Alerts when a mower enters or exits a prescribed area, for example if the mower has been stolen or an operator entered an area that should not be mowed.

- Curfews-Alerts if the mower is operating outside prescribed times, for example residential areas with early-morning noise restrictions.

Engine hours

The modem regularly transmits the mower’s engine hours to inform maintenance planning and balance use.

- Sync-The mower reports actual engine hours to the Operations Center.

- Key-Engine hours are estimated by monitoring the key switch. Engine hours can be corrected in Operations Center.

Maintenance planner

Operations Center Maintenance Planner

Operations Center Maintenance Planner

Factory or custom maintenance plans can be established in Operations Center. Maintenance alerts are sent when engine hours reach maintenance intervals.

Diagnostic trouble codes (DTCs)

On select products, the modem transmits the trouble codes generated by the mower’s control units to the Operations Center. Addressing DTCs can reduce downtime and repair costs. For example, a low-engine oil pressure DTC can indicate an engine is low on oil. Addressing the issue can prevent costly downtime and repairs.

Machine Analyzer Tool

Operations Center Machine Analyzer Tool

Operations Center Machine Analyzer Tool

On select products, the modem reports the time the mower spent transporting, idling, and working. The Operations Center’s Machine Analyzer tool reports usage data which allows you to analyze operator behavior, identify causes of low productivity, and initiate corrective actions.

Fuel level

On select products, the modem reports the fuel level. On these products, an analysis of fuel consumption is available in the Operations Center Machine Analyzer Tool. Measuring fuel consumption enables you to address causes of excessive fuel use.

Service Advisor Remote

On select products, John Deere dealers can perform remote diagnostics, software programming, and adjustments without the cost of a service call.

Compatibility

A JDLink M Modem is standard equipment on model year 2024 and newer (SN 110,001-) TerrainCut Front Mowers and model year 2024 and newer (SN 690,001-) TerrainCut Wide-Area Mowers.

A JDLink M Modem can be field installed on the commercial mowing products listed below. Field installation attachments simplify modem installation, and include brackets, mounting hardware, harness, and instructions. Field installation requires a JDLink M Modem to be ordered separately. The field installation attachments include a wiring harness therefore the modem should be ordered with the less harness option code.

Model |

Compatible model years |

Installation attachment |

Z700 ZTrak Mowers |

2024 and newer (SN 080,001-) |

BUC11759 |

Gasoline-powered Z900 ZTrak Mowers |

2024 and newer (SN 130,001-) |

BUC11759 |

Z994R ZTrak Mowers |

2024 and newer (SN 070,001-) |

BUC11759 |

Z997R ZTrak Mowers |

2021 and newer (SN 070,001-) |

BUC11908 |

QuikTrak Mowers |

2024 and newer (SN 010,001-) |

BUC11744 |

R Series commercial walk-behind mowers |

2025 and newer (SN 070,001-) |

BUC11918 |

TerrainCut Front Mowers |

2022-2023 (SN 080,001-110,000) |

BUC11797 |

1600 TerrainCut Wide-Area Mowers |

2023 (SN 680,001-690,000) |

BUC11797 |

Flat-free rear tire shown on ZTrak™ Mower

Flat-free rear tire shown on ZTrak™ Mower

John Deere provides the commercial mower industry with the Michelin X Tweel Turf technology for Commercial ZTrak Mowers:

- 24x12N12 as an ordering option code for ZTrak Gas Mowers with 48 in., 54 in., 60 in., and 72 in. (137-cm, 152-cm, and 183-cm) Mower Decks

- 24x12N12 is also available as base code equipment for ZTrak Gas Mowers with 48 in., 54 in., 60 in., and 72 in. (137-cm, 152-cm, and 183-cm) Mower Decks (ordering information available at Configurator on the Tweel model page)

- 24x12N12 as an ordering option code for ZTrak Z994R Diesel with 54 in., 60 in., and 72 in. (137-cm, 152-cm, and 183 cm) Mower Decks

- 26x12N12 as an ordering option code for Z997R Diesel with 60 in. and 72 in. (152-cm and 183-cm) Mower Decks

Michelin is a world leader in tire manufacturing and technology. This airless radial tire solution is an industry first for John Deere, which provides an additional advantage to John Deere customers.

Advantages of the Michelin X Tweel Turf include:

- Mowing performance is improved.

- Rutting is reduced because the Michelin X Tweel Turf has more support across the surface for improved flotation and better ground contact.

- Unique energy transfer within the poly-resin spokes reduces the bounce associated with pneumatic tires.

- Excellent curb climbing is possible due to the Michelin X Tweel Turf construction and flexibility.

- More consistent cut quality is achieved because inconsistent tire pressure is eliminated.

- Uptime is improved.

- The exclusive technology eliminates downtime and associated cost due to flat or damaged tires.

- Punctures and sidewall damage no longer result in downtime.

- Cost of operation is reduced.

- Cost of repairs and maintenance is reduced. One single unit replaces the current tire, wheel, and valve assembly. There is no need for complex tire-mounting equipment.

- No need to spend time checking and optimizing tire pressure.

- The need to purchase and stock plug kits and spare tires is eliminated, particularly for professional landscape contractors and government agencies who normally stock them.

- The tire tread will last up to three times longer than current pneumatic tires because automotive-grade rubber is used for the tread.

Michelin X Tweel Turf

Michelin X Tweel Turf

Michelin X Tweel Turf

Michelin X Tweel Turf

Heavy-duty construction provides the ultimate in performance and reliable operation:

- High-strength poly-resin spokes carry the load.

- Four-hole, heavy-duty steel hub for durability.

- Deep, open-tread design provides excellent cleaning and traction.

- Zero degree, high-tensile proprietary carcass provides great lateral stiffness while resisting damage from impact and penetration.

NOTE: In some cases, different size Tweel tires are required depending on the mower deck size.

Tires deliver exceptional traction and maneuverability

24x9.5-12 drive tire

24x9.5-12 drive tire

24x12-12 drive tire

24x12-12 drive tire

13x6.5-6 front flat-free semi-pneumatic caster tire

13x6.5-6 front flat-free semi-pneumatic caster tire

15x6-6 front flat-free semi-pneumatic tire

15x6-6 front flat-free semi-pneumatic tire

The ZTrak M Series Mowers with 48-in. (122-cm) mower decks come with 24x9.5-12 4 PR drive tires. M Series Mowers with 54-in. (137-cm), 60-in. (152- cm), and 72-in. (183-cm) decks come with 24x12-12 4 PR drive tires. All M Series Mowers are equipped with 13x6.5-6 front flat-free semi-pneumatic caster tires.

The ZTrak R Series Mowers with 48-in. (122-cm) mower decks come with 24x9.5-12 4 PR drive tires. R Series Mowers with 54-in. (133-cm), 60-in. (152-cm) and 72-in. (183-cm) decks come with 24x12-12 4 PR drive tires. All R Series Mowers are equipped with 15x6-6 front flat-free semi-pneumatic tires.

The tires provide:

- Excellent traction, flotation, and curb climbing

- Low center of gravity to increase hillside mowing capability

- Caster wheels and caster wheel towers with sealed bearings for long life and easy steering

- Offset front caster wheels to help improve the inside corner-trim performance and reduce between-blade striping

Michelin, X, and Tweel are trademarks of Compagnie Générale des Etablissements Michelin SCA.

Propane conversion kit on a walk-behind mower

Propane conversion kit on a walk-behind mower

Dual propane conversion kit on a QuikTrak™ Mower

Dual propane conversion kit on a QuikTrak™ Mower

John Deere provides application-specific Environmental Protection Agency (EPA) approved field-installed propane conversion kits for specific John Deere commercial walk-behind mowers, QuikTrak Mowers, and commercial ZTrak™ Mowers. The conversion kits include all components required to convert the engines to operate on propane fuel. Single-tank or dual-tank brackets (depending on the vehicle) are provided for securely holding the propane tank(s) to the vehicle.

Propane tanks are not included.

An optional altitude kit is required when operating at altitudes above 2000 ft (610 m). The operator’s manual with the propane conversion kit provides further details. Parts must be ordered separately through John Deere Parts.

Propane facts:

- Propane is flammable and commonly used as a fuel.

- The molecular formula of propane is C3H8, and it is in the family of liquefied petroleum gases (LP gases). The other LP gases include butane, propylene, butadiene, butylene, isobutylene, and mixtures thereof.

- Propane is commonly available and has proven to be a dependable, safe, economical, and clean-burning fuel. It can be used as household fuel, industrial fuel, and fuel for internal combustion engines. Propane has been used as a fuel since 1910.

- At atmospheric pressure, propane boils at -44°F (-42.2°C), meaning it typically exists as a vapor. However, when contained under pressure, such as in a propane cylinder, it can exist as a liquid.

- Propane is naturally odorless, but includes an additive odorant, usually mercaptan, which gives it a distinct odor.

- Vapor propane is heavier than air, meaning it will settle in low areas such as along the ground or in drains.

Advantages of John Deere propane conversion kits include:

- Reduced fuel costs up to 30 percent depending on fuel prices

- Lower emissions

- Reduced fuel-system maintenance

- Maintains John Deere warranty

- EPA and CARB certified

- May qualify for national and state rebate and incentive programs.

Propane tank mounting bracket options:

Single propane tank shown on QuikTrak Mower

Single propane tank shown on QuikTrak Mower

Dual propane tanks shown on ZTrak Mower

Dual propane tanks shown on ZTrak Mower

Optional tank configurations and sizes are available to provide operators the ability to tailor for run time:

- Commercial walk-behind mowers have only a single-tank mounting option.

- The single-tank bracket is designed for one 20-lb (9.1-kg) Worthington tank.

- Tank is not included.

- The single-tank bracket is designed for one 20-lb (9.1-kg) Worthington tank.

- Model year 2023 and older QuikTrak Mowers have single-tank and dual-tank mounting options.

- The single-tank, right-side bracket is designed for one 33-lb (15-kg) Worthington tank.

- Tank is not included.

- The dual-tank brackets are designed for two 20-lb (9.1-kg) Worthington tanks.

- Tanks are not included.

- The single-tank, right-side bracket is designed for one 33-lb (15-kg) Worthington tank.

- Model year 2024 and newer QuikTrak Mowers have only a dual-tank mounting option.

- The dual-tank brackets are designed for two 33-lb (15-kg) Worthington tanks.

- Tanks are not included.

- The dual-tank brackets are designed for two 33-lb (15-kg) Worthington tanks.

- ZTrak Mowers have single-tank and dual-tank mounting options.

- The single-tank, left-side bracket is designed for one 33-lb (15-kg) or 43-lb (19.5-kg) Worthington tank.

- Tank is not included.

- The dual-tank brackets are designed for two 33-lb (15-kg) Worthington tanks.

- Tanks are not included.

- ZTrak Mowers with dual-tank configurations are not compatible with any material collection systems.

- The single-tank, left-side bracket is designed for one 33-lb (15-kg) or 43-lb (19.5-kg) Worthington tank.

NOTE: Reference the Propane and Attachment Compatibility Chart to determine tank configurations that are compatible.

Estimated run-time comparison

| Engine displacement | FS603cc | FS726cc | FX726cc | FX852cc |

| Average consumption (lb [kg]/hr) | 3.9 (1.8) | 4.2 (1.9) | 4.2 (1.9) | 5.8 (2.6) |

| Run time (hours) with 20-lb (9.1-kg) tank | 5.1 | 4.8 | 4.8 | 3.4 |

| Run time (hours) with 33.5-lb (15.2-kg) tank | Not available | 8.0 | 8.0 | 5.8 |

| Run time (hours) with 43.5-lb (19.7-kg) tank | Not available | 10.4 | 10.4 | 7.5 |

specs

| Engine Manufacturer/model | FX850V |

| Engine power | Gross at 3,600 rpm 27 hp 20.1 kW |

| Fuel tank capacity | 11.5 U.S. gal. 43.5 L |

| Mower deck size | 54-in. (137-cm) 7Iron™ PRO side-discharge 60-in. (152-cm) 7Iron™ PRO side-discharge 72-in. (183-cm) 7Iron™ PRO side-discharge 60-in. (152-cm) FastBack™ PRO rear-discharge |

| Blade tip speed | 7Iron PRO: Approximately 18,500 fpm 60-in. (152-cm) FastBack: Approximately 16,500 fpm |

| Transmission | Hydrostatic |

| Speed range | 0-12 mph 0-19.3 km/h |

| Drive wheels | 24x12-12 |

| Caster wheels | 13x6.5-6 |

| Warranty | 36 months or 1500 hours, whichever comes first First 24 months, no hour limitation |

| Manufacturer/Model | FX850V |

| Power | Gross at 3,600 rpm 27 hp 20.1 kW |

| Displacement | 52 cu in. 852 cc |

| Cylinders | Two |

| Crankcase capacity | With filter, 2.4 U.S. qt 2.3 L |

| Oil filter | Full flow, replaceable |

| Lubrication | Full pressure |

| Cooling | Air |

| Air cleaner | Pre-cleaner Yes Heavy-duty canister type with safety element |

| Fuel type | Gasoline |

| Fuel consumption | Under normal conditions, load, operation, and dependent on loads and operating conditions 1.1-1.9 U.S. gal./hr 4.2-7.2 L/hr |

| Fuel tank capacity | 11.5 U.S. gal. 43.5 L |

| Fuel tank switch/shut-off valve | Yes |

| Charge system | 30 amp |

| Battery voltage | 12 V |

| Cold cranking amp | 300 amp |

| Hour meter | Standard, digital |

| Operator presence starting system | Brake-N-Go (foot) |

| Transmission | Hydrostatic |

| Wheel motors | Tuff Torq heavy-duty integrated piston wheel motor |

| Travel speed | Speed range 0-12 mph 19.3 km/h Forward 0-12 mph 19.3 km/h Reverse 0-4.5 mph 0-7.2 km/h |

| Speed and direction control | Twin levers |

| Hydraulic capacity | 5.9 U.S. qt 5.6 L |

| Filter | Internal, replaceable |

| Warranty | 36 months or 1500 hours, whichever comes first First 24 months, no hour limitation |

| Drive wheels | 24x12-12 |

| Load rating | 4 PR |

| Dynamic braking | Twin levers |

| Park brake | Internal wet disk integrated in the transmission |

| Park brake actuation | Foot brake |

| Type | Electro-magnetic, 225 lb-ft 305 Nm |

| Drive | V-belt |

| Size | 54-in. (137-cm) 7Iron™ PRO side-discharge 60-in. (152-cm) 7Iron™ PRO side-discharge 72-in. (183-cm) 7Iron™ PRO side-discharge 60-in. (152-cm) FastBack™ PRO rear-discharge |

| Deck construction | 7-Iron™ PRO: 7-gauge, 0.179-in. (4.6-mm) one-piece forged steel FastBack™ PRO: 7-gauge, 0.179-in. (4.6-mm) fabricated steel |

| Height-of-cut range | Increments 0.25 in. 0.64 cm 1-5.5 in. 2.54-14 cm |

| Cutting width | 60, 72 in. 152, 183 cm |

| Length | Varies by deck size |

| Thickness | 0.25 in. 0.64 cm |

| Blade tip speed | 7Iron PRO: Approximately 18,500 fpm 60-in. (152-cm) FastBack: Approximately 16,500 fpm |

| Number | Three |

| Caster wheel type | Flat free |

| Caster wheels | 13x6.5-6 |

| Front anti-scalp rollers | RH, center, LH |

| Rear anti-scalp rollers | Standard |

| Length | 84 in. 213 cm |

| Width | With chute down, 74, 86 in. 188, 218 cm Rear discharge, 63.5 in. 161.3 cm |

| Height | With ROPS up, 73 in. 185 cm With ROPS down, 47 in. 119 cm |

| Weight | 1,315 to 1,423 lb 596 to 645 kg |

| Rollover protective structure (ROPS) | Yes |

| Slope operating limit | 20 degrees (10 degrees with material collection system installed) |

| Date collected | 1-Aug-24 |

Offers & Discounts

No Payment, No Interest for 6 months, followed by 3.9% APR fixed rate for 42 months on new John Deere Commercial Mowing Equipment

- No Payment, No Interest for 6 months, followed by 3.9% APR fixed rate for 42 months1

- Offer available 03 June 2025 through 31 July 2025

1Offer valid on qualifying purchases made 03 June 2025 through 31 July 2025. Subject to approved installment credit with John Deere Financial, for consumer and commercial use only. Down payment may be required. Average down payment is 10%. No payment, no interest for 6 months, followed by 3.9% APR for 42 months. Taxes, freight, setup, insurance, fees, and delivery charges could increase monthly payment. Sales made to government agencies, company direct sales or other businesses/agencies that participate in John Deere's Special Discount Program or in John Deere's Rental Business Program are not eligible. Available at participating U.S. dealers. Prices and models may vary by dealer. Offer available on new equipment and in the U.S. only. Prices and savings in U.S. dollars.

0% APR fixed rate for 24 months on New John Deere Z900 Series ZTrak Zero-Turn Commercial Mowers

- 0% APR fixed rate for 24 months1 OR

- 1.9% APR fixed rate for 36 months2 OR

- 2.9% APR fixed rate for 48 months3

- Offers available 03 June 2025 through 31 July 2025

1Offer valid on qualifying purchases made 03 June 2025 through 31 July 2025. Subject to approved installment credit with John Deere Financial, for consumer and commercial use only. Down payment may be required. Average down payment is 10%. $41.67 per month for every $1,000 financed. 0% APR for 24 months only. Taxes, freight, setup, insurance, fees, and delivery charges could increase monthly payment. Sales made to government agencies, company direct sales or other businesses/agencies that participate in John Deere's Special Discount Program or in John Deere's Rental Business Program are not eligible. Available at participating U.S. dealers. Prices and models may vary by dealer. Offer available on new equipment and in the U.S. only. Prices and savings in U.S. dollars.

2Offer valid on qualifying purchases made 03 June 2025 through 31 July 2025. Subject to approved installment credit with John Deere Financial, for consumer and commercial use only. Down payment may be required. Average down payment is 10%. $28.60 per month for every $1,000 financed. 1.9% APR for 36 months only. Taxes, freight, setup, insurance, fees, and delivery charges could increase monthly payment. Sales made to government agencies, company direct sales or other businesses/agencies that participate in John Deere's Special Discount Program or in John Deere's Rental Business Program are not eligible. Available at participating U.S. dealers. Prices and models may vary by dealer. Offer available on new equipment and in the U.S. only. Prices and savings in U.S. dollars.

3Offer valid on qualifying purchases made 03 June 2025 through 31 July 2025. Subject to approved installment credit with John Deere Financial, for consumer and commercial use only. Down payment may be required. Average down payment is 10%. $22.09 per month for every $1,000 financed. 2.9% APR for 48 months only. Taxes, freight, setup, insurance, fees, and delivery charges could increase monthly payment. Sales made to government agencies, company direct sales or other businesses/agencies that participate in John Deere's Special Discount Program or in John Deere's Rental Business Program are not eligible. Available at participating U.S. dealers. Prices and models may vary by dealer. Offer available on new equipment and in the U.S. only. Prices and savings in U.S. dollars.

$500 Off on New John Deere Z900 non EFI Gas ZTrak Zero-Turn Mowers & Commercial Walk-Behind Mowers

- $500 Off1

- Offer available 03 June 2025 through 02 July 2025

1Offer valid on qualifying new purchases made 03 June 2025 through 02 July 2025. Prices and models may vary by dealer. $500 USD off the agreed upon purchase price of New John Deere Z900 non EFI Gas ZTrak™ Zero-Turn Mowers & Commercial Walk-Behind Mowers only. This can be combined with promotional finance incentives. Sales to government agencies, company direct sales or other businesses/agencies that participate in John Deere's Special Discount Program or Rental Business Program are not eligible. Other restrictions may apply. See participating dealer for details and other financing options. Offer is available only at participating United States dealers. Prices and savings are in U.S. dollars.

Similar Products

Reviews

5.0

(1 review)Prices and availability may vary by dealer. Taxes not included. Images for illustration purposes only. Financing subject to approved credit by John Deere Financial. Down payment may be required to receive financing. Restrictions may apply outside of Hutson’s area of responsibility. See dealer for details.